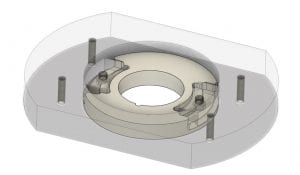

This part was a replacement and particularly tricky as it had some tight tolerances. It was made with CAD design, Laser cutting and CNC milling.

It could have been 3D printed but the requirements were for it to be thick, hard, flat and smooth on the bottom surface so it could freely slide over the work it was cutting. An offcut piece of 10mm Acrylic was selected to be suitable stock material. This selection limited the manufacture methods to be only subtractive.

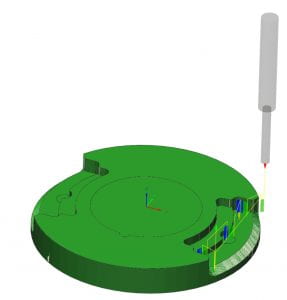

- Firstly the router base was reverse engineered and drawn up in Fusion 360. All relevant areas were carefully measured to produce the best model possible

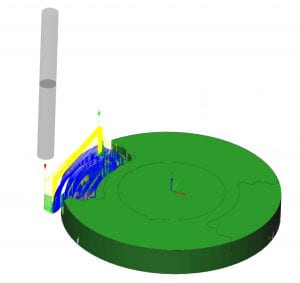

- The tool pathing was then programmed using the Fusion 360 manufacturing workspace, simulated and post-processed to get the correct output file for the machine. The tools used must be correct for the machine and in the correct tool rack locations.

- The missing insert was then designed to fit the reverse-engineered CAD model taking into account any areas that would need to be controlling features or that needed clearance. It is good practice to only have only one controlling feature to fix parts in place per plane. I.e. a pin in a close hole to fix in the X & Y plane, a pin in a slot to fit the rotation and a screw to pull in the Z plane to pull up against and stop it moving off the pins.

- Next, the material was laser cut to be slightly larger than final dimensions (about +0.5mm per side) and include some fixturing points for secure mounting in the CNC machine. This was done as it is a faster process than using the CNC machine to cut the entire part out.

- The net shape part was then secured to a piece of waste board with screws, then mounted into the CNC for the machining of the tight tolerance areas. It is a good idea to produce features that need to be specific dimensions to each other in one machine set up to make the machine control the accuracy.

- The part was then machined to produce the required pockets to fasten to the router base and clean up the outside perimeter to have a close fit when installed.