Welcome to the Design Technicians website

Kia ora!

Welcome to the DesignLab website! This is the virtual home of the design technicians and where we post useful information, links, and articles related to Design.

Please check back on a regular basis and feel free to contact the technicians with all of your tech-related questions.

Nga mihi

Our Equipment & Machines

3D Printing

Additive manufacturing technique for rapid prototyping that uses filament

Spatial Computing Lab

Hybrid computer space for film, mocap, and content creation

Soldering Stations

Join two metal surfaces together using solder – used for electronics

Electronics

List of components that we have in the workshop ready for you to purchase

Laser Cutting

Cut and etch into a variety of both flat and round materials/objects

Water Jet Cutting

Similar to a laser cutter but cuts using water at high pressure

CNC Routing

Moving a tool to a specific x, y, and z coordinates to cut away material

Vacuum Forming

Heat up a plastic sheet and form it over your object – good for mould making

Spray Booth

We have 2 types of paint spray-guns that you can use with waterbase paints

Machine & Material Credits

See what materials we have in the lab and purchase them through the CAI store

Sewing Station

Use our craft station complete with an overlocker to create patterns and garments

Embroidery Machine

Our new digital embroidery machine converts digital artwork into textiles

Vinyl/Sticker Cutting

Print and cut out custom stickers and vinyls that can be used for decorations

Badge Making

Easily create custom badges with a variety of backing options

Cricut Machine

Cut, draw, and emboss different materials with precision

Workshop Calendar

Our standard hours are 9am – 4pm but these can vary depending on deadlines etc.

Meet the Technicians

Jamie

Senior Technician (He/Him)

With a background as a Mechanical and Software Design Engineer, he is a great all-rounder in hands-on creation, digital fabrication, programming microcontrollers, electronics, CAD Design and general tinkering. With special interests in automation, electronics design and vehicle engines.

Aldo

Technician (They/Them)

Electronics and game development master. Aldo has gained industry experience through their NZ game design company along with their tenure at multiple game development companies. They are a tinkerer who is always ready to share their knowledge.

Jillian

Technician (She/Her)

Having worked as a graphic, packaging, and industrial designer, Jillian has industry experience with both digital and physical mediums. She is passionate about silicone and ceramic casting, sewing, 3D printing, and the Adobe Creative Suite.

Sam

Technician (She/Her)

With a background as a designer making products, props and installations, Sam has worked in environments ranging from early-stage startups to hospital-led research projects and film productions. She is passionate about rapid prototyping for usabability, to create impactful designs.

Where to find us

We are located in the Design Lab within the engineering building 402, level 3, room 340.

The Design Lab is next to the Design Studios and one level under the Unleashed Space.

Our standard hours are 9am – 4pm but these can vary depending on deadlines etc.

Contact Us

For more information, you can drop in or contact us via email at designtech@auckland.ac.nz

This blog is primarily for students at the University of Auckland

Check out our Projects page for tips and tricks

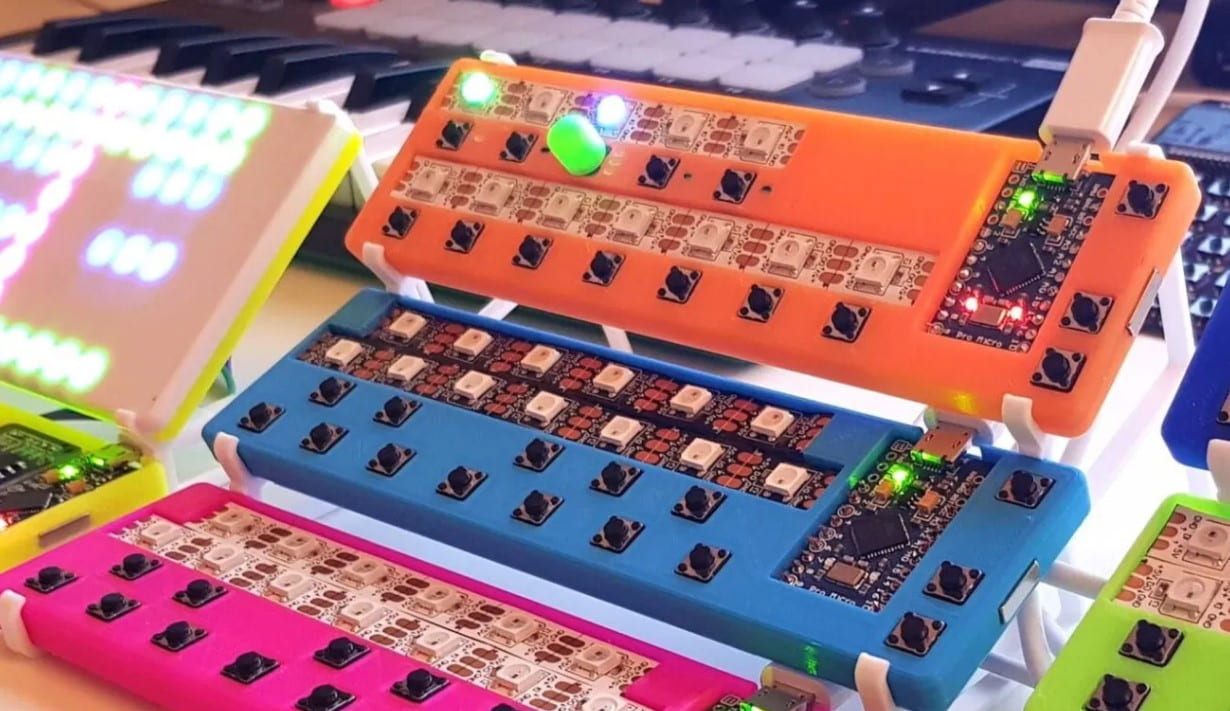

LEET Modular Synth

LEET is Johan Von Konow’s modular affordable synth you can build yourself. It consists of several MIDI devices that can be used together or separate with your preferred DAW. This page includes the 3d print file, the code, and an innovative circuit board system. Other...

Circuito.io

www.circuito.io is a useful prototyping tool for electronic schematics. Use this to get an idea of how you might wire up your projects.

Plastics Recycling

Here are a few resources and interesting links to plastics recycling projects, companies and ideas Precious Plastics https://community.preciousplastic.com/academy/plastic/basics ODF Recycled Plastic Design https://www.recycledplasticdesign.com/pages/our-story...