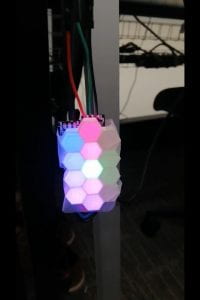

This project was started to address the unattractive back of the PC in the tech office that is one of the first sights to greet guests to the Design Facility.

As well as making the space look better we could display students processing projects that are suitable for low resolution displays.

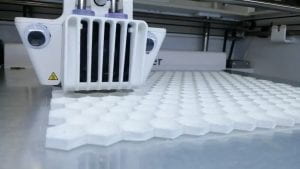

I have always wanted to make individual diffusion cells for led displays but without access to a 3d printer it was a very time consuming project.

Jamie found that if you design a wall in fusion with the same thickness as the nozzle on the 3d printer you can create a single thickness 3d printed wall out of white PLA that diffuses LED light very well.

The size of the Hexagons is based on the gap between leds on WS2912b smart pixel strips – i made two different sizes based on 96 Led per meter and a 75 led per meter strip sizes

Hexagon Led diffuser test

Hex diffuser printing

Hexagon Computer Display situated in Design Tech lab

The data to control the strips comes from a fade candy board that is controlled by a processing sketch the power comes from a USB phone charger